Building AREMA Standard Steel Rail Railway Crane Iron Rail

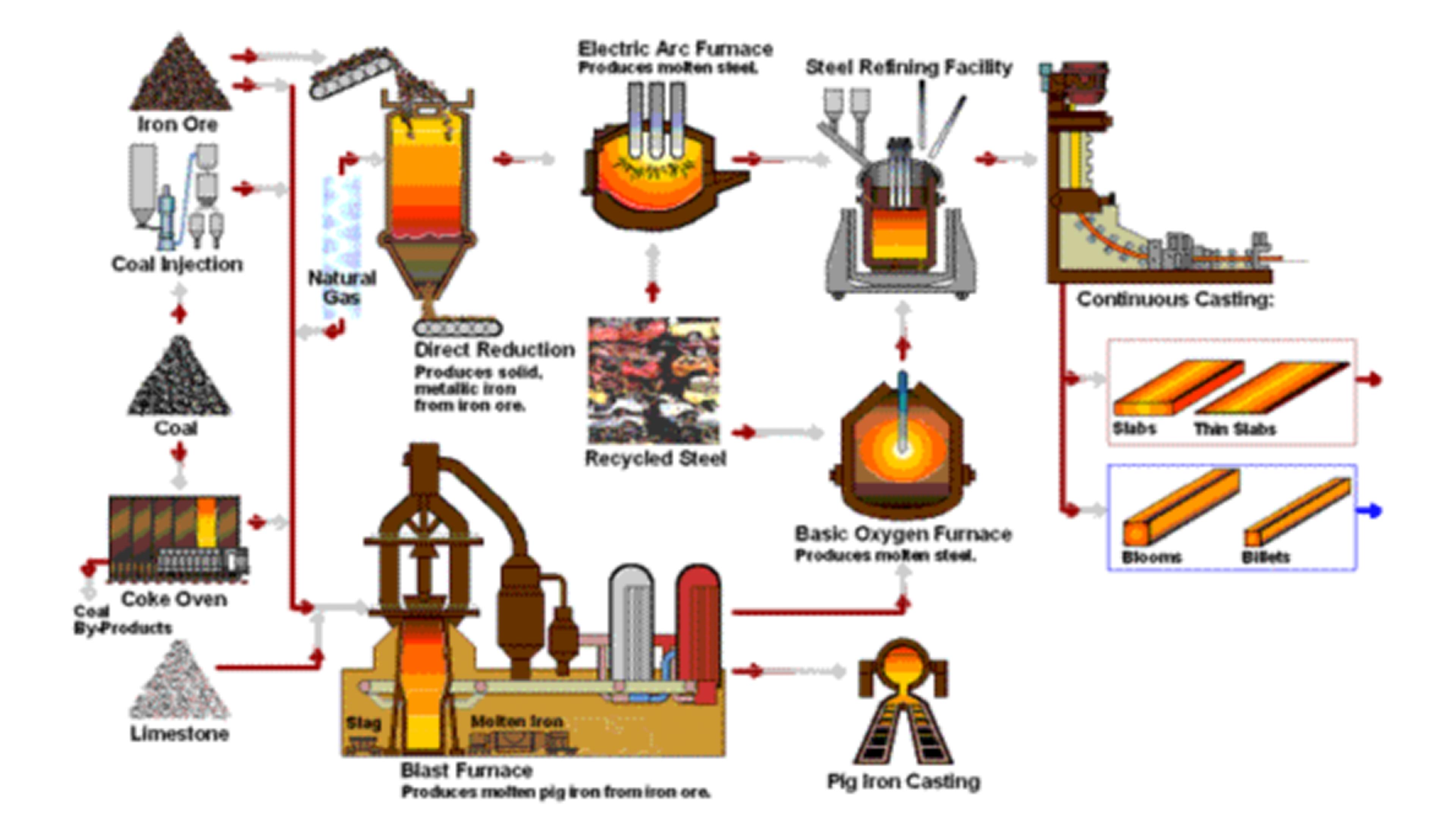

The production process of AREMA standard steel rail usually includes the following steps:

Raw material preparation: Prepare raw materials for steel, usually high-quality carbon structural steel or low alloy steel.

Smelting and casting: The raw materials are smelted, and then the molten steel is cast into preliminary steel billets through continuous casting or pouring.

Refining and rolling: Refining the preliminary steel billet, including removing impurities and adjusting the composition, and then rolling the steel billet through rolling equipment into track billets that meet national standards.

Pretreatment: Pretreatment of track billets, including forging, heat treatment and surface treatment, etc., to improve the strength and durability of the rails.

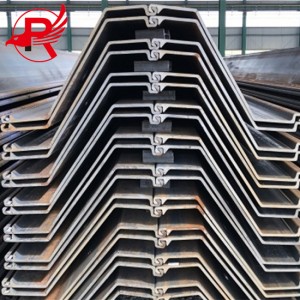

Rolling and forming: The pre-treated track billet is rolled and formed through a rolling machine to make it into a rail profile that meets the national standard requirements.

Inspection and quality control: Strict inspection and quality control are carried out on the produced rails to ensure that they meet national standards and customer requirements.

Packaging and leaving the factory: Qualified rails are packaged and marked, and then delivered to the customer or stored in the warehouse waiting for shipment.

PRODUCT PRODUCTION PROCESS

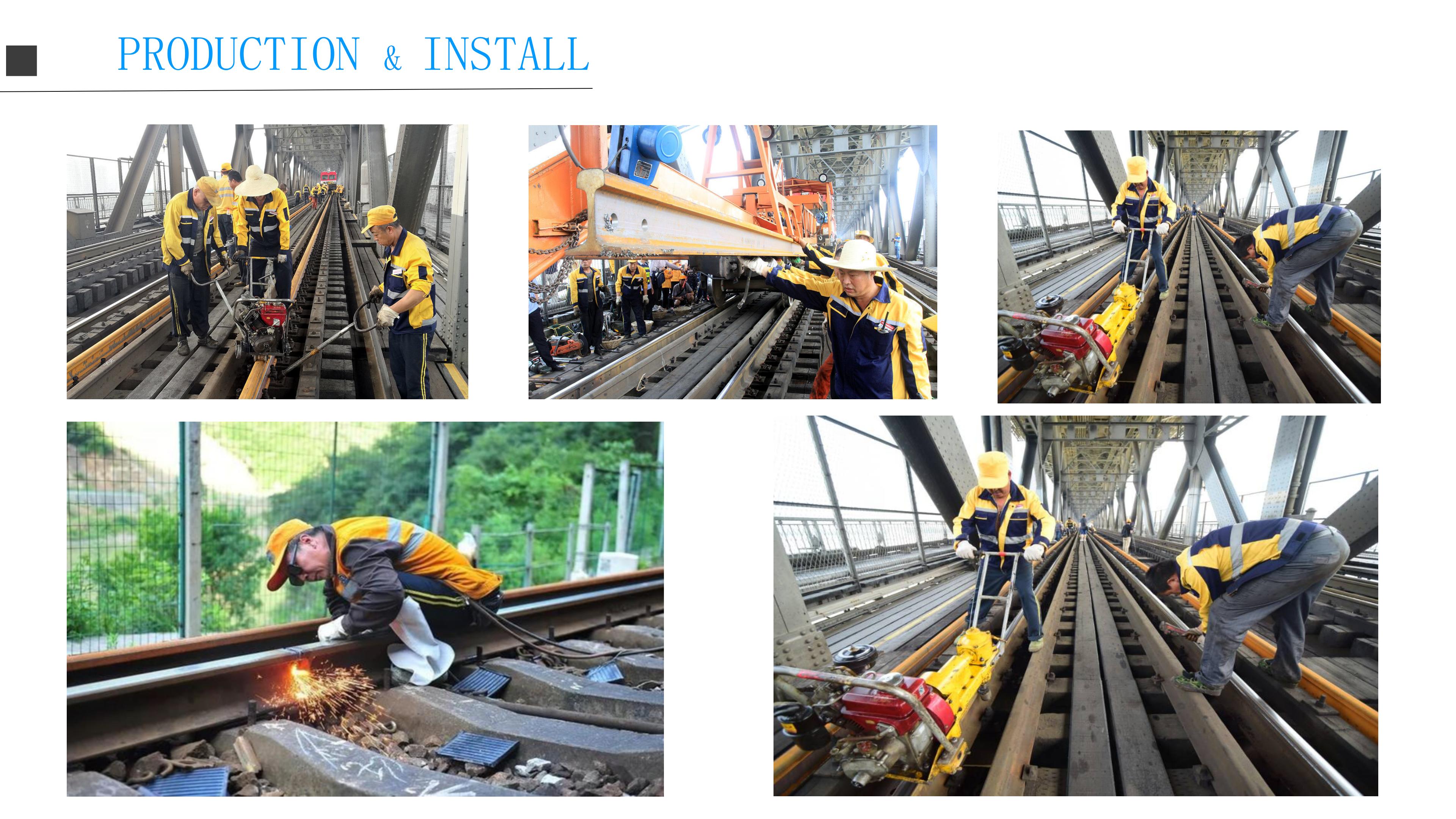

Technology and Construction Process

The process of constructing ASTM standard steel rail tracks involves precision engineering and careful consideration of various factors. It begins with designing the track layout, taking into account the intended usage, train speeds, and terrain. Once the design is finalized, the construction process commences with the following key steps:

1. Excavation and Foundation: The construction crew prepares the ground by excavating the area and creating a sturdy foundation to support the weight and stress imposed by trains.

2. Ballast Installation: A layer of crushed stone, known as ballast, is laid on the prepared surface. This serves as a shock-absorbing layer, providing stability, and helping to distribute the load evenly.

3. Ties and Fastening: Wooden or concrete ties are then installed on top of the ballast, imitating a frame-like structure. These ties offer a secure base for the steel railroad tracks. They are fastened using specific spikes or clips, ensuring they remain firmly in place.

4. Rail Installation: The steel railroad rails 10m, often referred to as standard rails, are meticulously laid on top of the ties. Being made of high-quality steel, these tracks possess remarkable strength and durability.

Excellent material: American standard rails are usually made of high-quality carbon structural steel or alloy steel, which has high strength and durability.

Standardization: Complying with American Railroad Association (AREMA) standards ensures the quality and safety of the track.

Wear resistance: The surface of American standard rails is usually specially treated to improve its wear resistance and extend its service life.

| United States standard steel rail | |||||||

| model | size (mm) | substance | material quality | length | |||

| head breadth | altitude | baseboard | waist depth | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| ASCE 25 | 38.1 | 69.85 | 69.85 | 7.54 | 12.4 | 700 | 6-12 |

| ASCE 30 | 42.86 | 79.38 | 79.38 | 8.33 | 14.88 | 700 | 6-12 |

| ASCE 40 | 47.62 | 88.9 | 88.9 | 9.92 | 19.84 | 700 | 6-12 |

| ASCE 60 | 60.32 | 107.95 | 107.95 | 12.3 | 29.76 | 700 | 6-12 |

| ASCE 75 | 62.71 | 122.24 | 22.24 | 13.49 | 37.2 | 900A/110 | 12-25 |

| ASCE 83 | 65.09 | 131.76 | 131.76 | 14.29 | 42.17 | 900A/110 | 12-25 |

| 90RA | 65.09 | 142.88 | 130.18 | 14.29 | 44.65 | 900A/110 | 12-25 |

| 115RE | 69.06 | 168.28 | 139.7 | 15.88 | 56.9 | Q00A/110 | 12-25 |

| 136RE | 74.61 | 185.74 | 152.4 | 17.46 | 67.41 | 900A/110 | 12-25 |

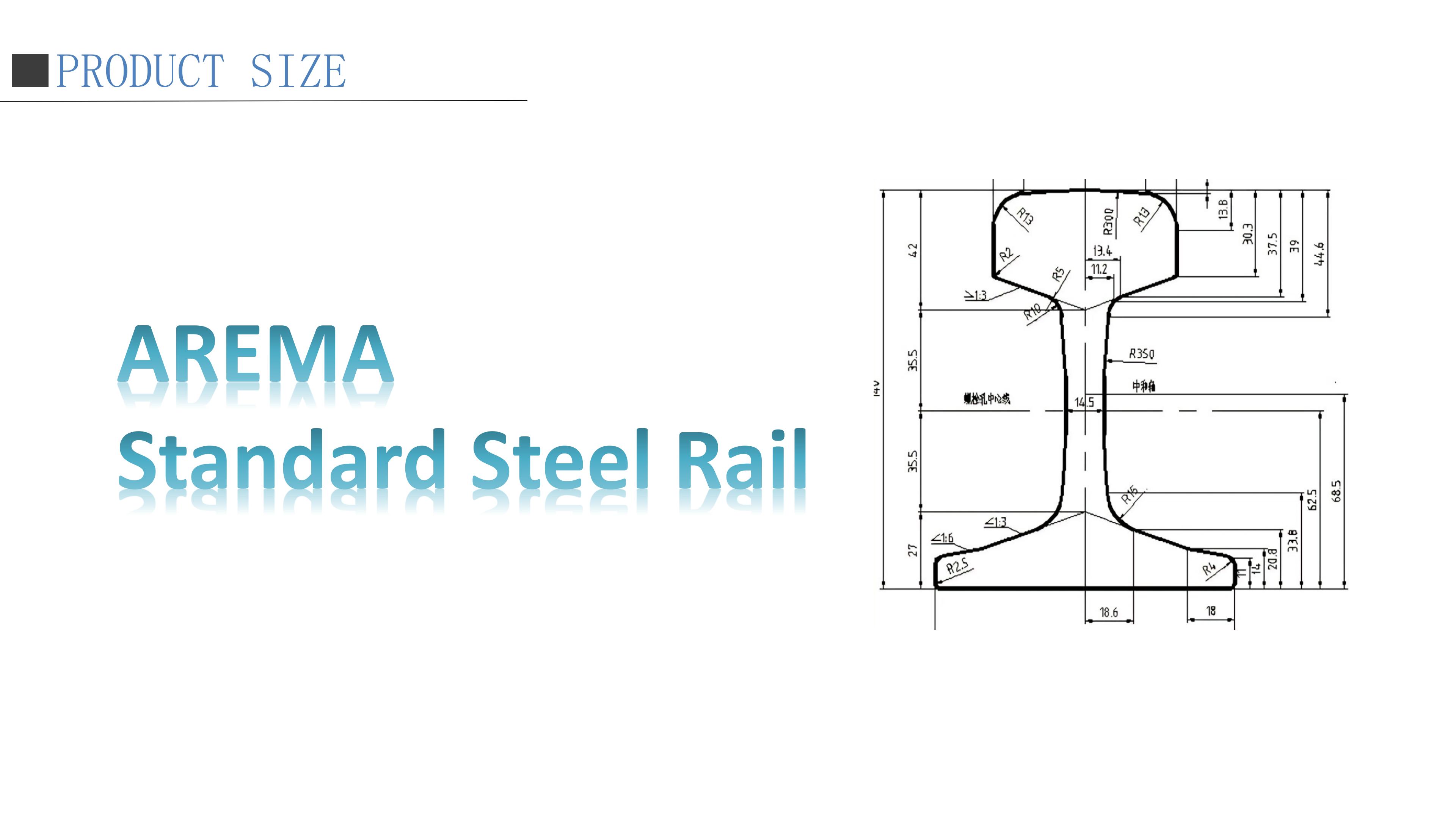

AREMA standard steel rail

Specifications: ASCE25, ASCE30, ASCE40, ASCE60,ASCE75,ASCE85,90RA,115RE,136RE,175LBs

Standard: ASTM A1,AREMA

Material: 700/900A/1100

Length: 6-12m, 12-25m

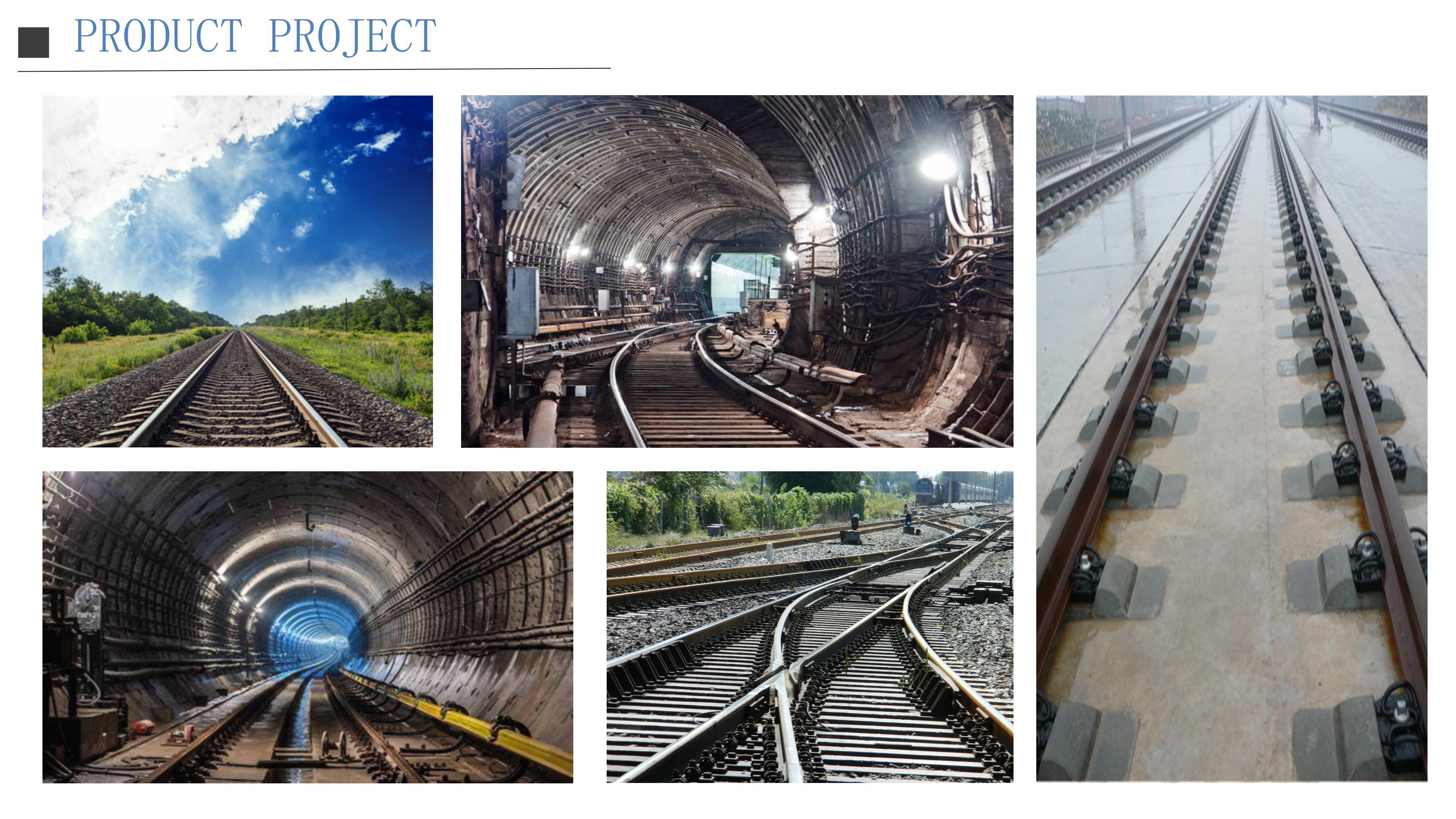

PROJECT

Our company’s 13,800 tons of Railroad Track for sale exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: [email protected]

ADVANTAGE

High strength: railway steel are usually made of high-quality carbon structural steel or alloy steel, which have high strength and load-bearing capacity and can withstand the weight and operating pressure of the train.

Wear resistance: The surface of American standard rails has been specially treated to improve its wear resistance, extend its service life and reduce maintenance costs.

Anti-corrosion: The surface of the rail may be treated with anti-corrosion to enhance its corrosion resistance and adapt to different environmental conditions, especially for better durability in humid or corrosive environments.

Standardization: Compliance with Association of American Railroads (AREMA) standards ensures the quality and safety of the track, making it suitable for rail systems within the United States.

Diversification: American standard rails can provide different specifications and models of rails according to different use needs to adapt to different railway lines and train operation requirements.

Reliability: American standard rails undergo strict quality control and have stable performance and reliable quality, ensuring the safe and stable operation of the railway system.

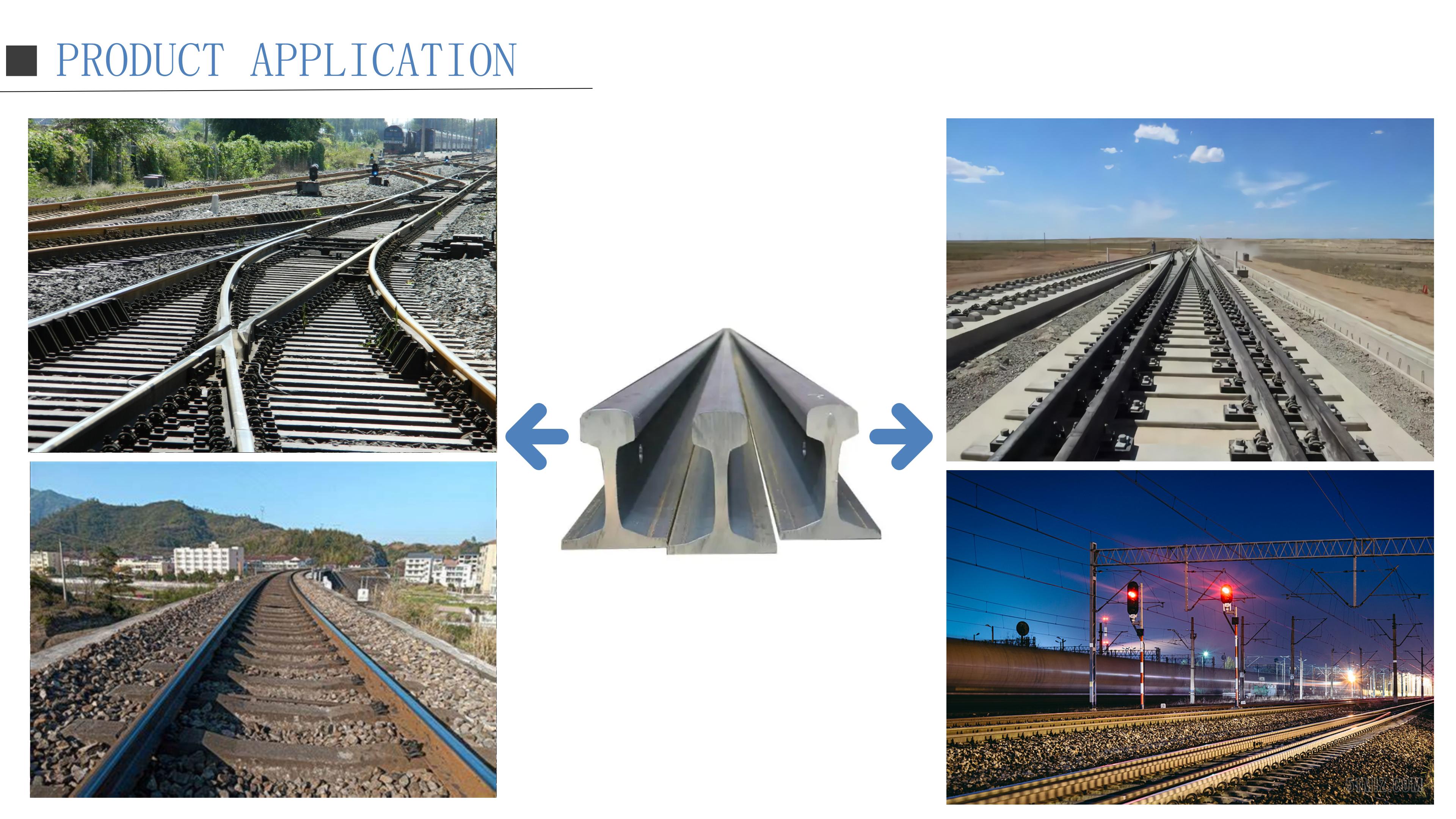

APPLICATION

American standard steel rails are mainly used in the American railway system as tracks for trains to travel. They carry the weight of the train, provide a stable route, and ensure that the train can operate safely and efficiently. American Standard rails are usually made of high-strength steel and can withstand heavy pressure and continuous use, so they play a vital role in rail transportation in the United States. American standard rails can also be used in some special occasions, such as narrow-gauge railways in mines and special railways in factories. Overall, American Standard rails are an integral part of the U.S. rail transportation system.

PACKAGING AND SHIPPING

American standard rails require special attention to protection and safety during packaging and transportation. The usual packaging and transportation methods are as follows:

Packaging: American Standard rails are usually bundled with steel straps or wire ropes to ensure that the rails will not move or be damaged during transportation. In addition, wooden or steel supports will be installed at both ends of the track to prevent bundling from damaging the track.

Transportation: American Standard rail is usually shipped by rail or road. During transportation, it is necessary to ensure that the rails are strapped firmly to avoid loosening or tilting. For rail transportation, it is necessary to ensure that the track matches the rolling stock to ensure safe transportation.

Unloading: During the unloading process, professional lifting equipment needs to be used to ensure the safe unloading of the track and avoid damage to the track.

COMPANY STRENGTH

Our company’s 13,800 tons of steel rails exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: [email protected]

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.