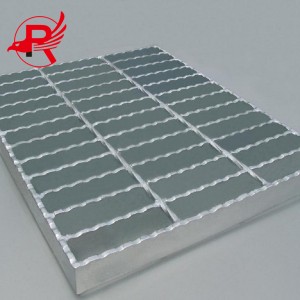

GB Steel Grating metal grating floor | expanded metal grating | steel grating for drainage | steel platform panel

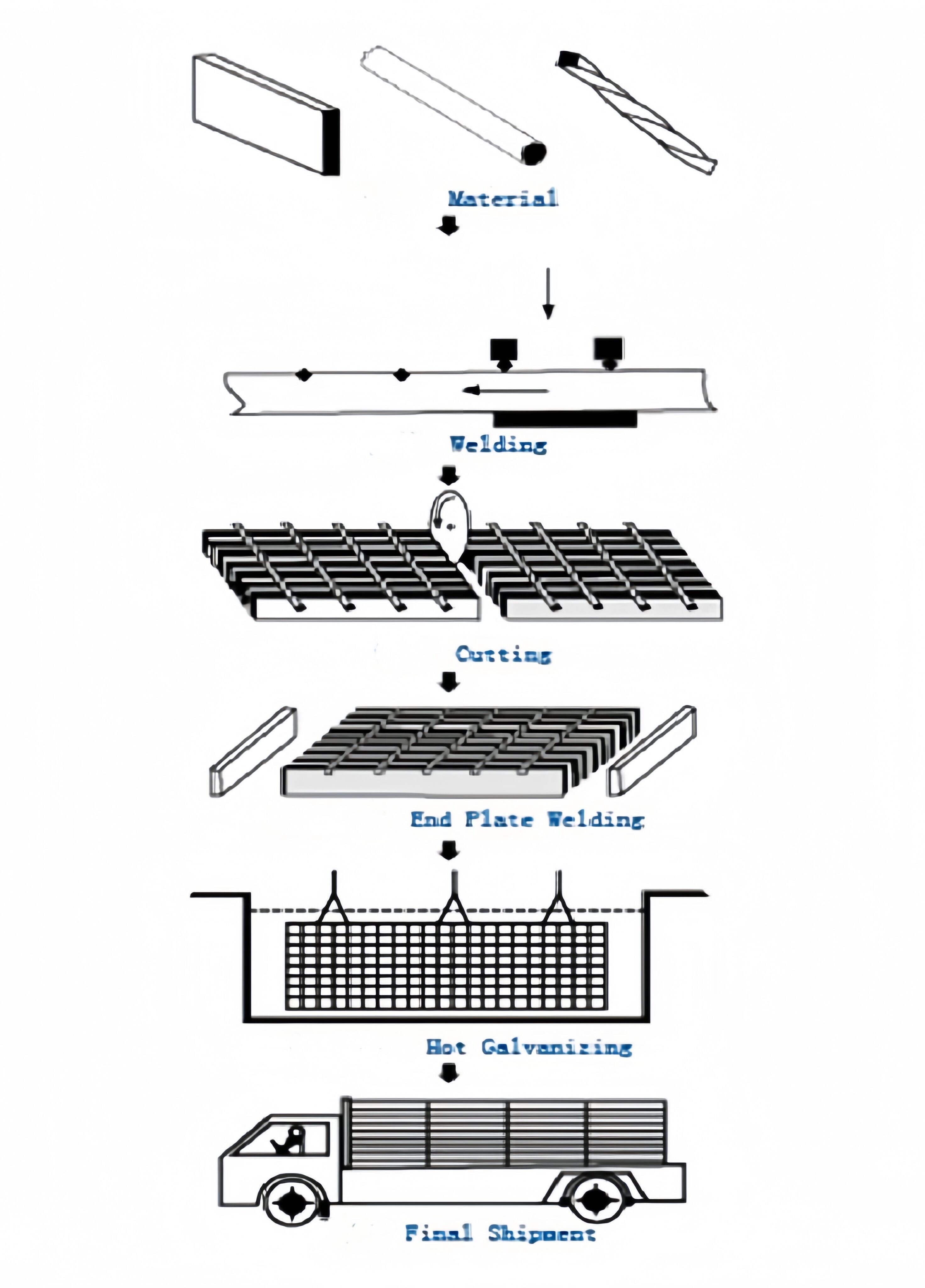

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Product name

|

Toothed steel grating

|

|

Design style

|

Modem

|

|

Material

|

Hot Galvanizing, customized

|

|

Weight

|

7-100kg

|

|

Bearing Bar

|

253/ 255/303/325/ 405/553/655

|

|

Bearing bar pitch

|

30mm 50mm 100mm

|

|

Feature

|

Excellent Anti-corrosion Resistance, anti-slip

|

|

Raw material

|

Hot Dipped Galvanized Steel Q235

|

|

Standard

|

European Standards,GB/T13912-2002,BS729,AS1650

|

|

Weld Way

|

Automatic Pressure Resistance Welding

|

| Chart column | empty of goods between |

Live space | Load flat mesh specifications (width and thickness) | |||||||

| 20x3 | 25x3 | 32x3 | 403 | 20x5 | 25x5 | |||||

| 1 | 30 | 100 | G20330100 | E25230H00 | C32380F100 | G40230100 | E205/30100 | E255/307100 | ||

| 50 | G20230/50 | C253/20/50 | C2233050 | 640340100 | C205/00/50 | C255/30/50 | ||||

| 2 | 40 | 100 | 6203/401100 | 8253/40100 | E323/401100 | 640340100 | 8205/40/100 | 5255/40/100 | ||

| 50 | G20340/50 | G250/40/50 | G223/4050 | G403140/50 | 205/4/50 | G255/4050 | ||||

| 3 | 60 | 50 | G203460/50 | C25360/50 | 5253/6050 | 3403480150 | C205/60/50 | G255/60150 | ||

| Chart column | empty of goods between |

Live space | Load flat mesh specifications (width and thickness) | |||||||

| 32×5 | 40x5 | 45x5 | 5045 | 55×5 | 80x5 | |||||

| 1 | 30 | 100 | G325301100 | G40530H00 | C45580100 | G50530100 | G555/30100 | E805/30/100 | ||

| 50 | G325/30/50 | C405/20/50 | G455/3050 | S505/30/50 | 55500/50 | G605/8050 | ||||

| 2 | 40 | 100 | 8325401100 | 840540100 | 455/40100 | G50540100 | 8555/40/100 | 2605/40/100 | ||

| 50 | G32540/50 | C405/40/50 | G4554050 | G505/40/50 | E555/40/50 | G605/40150 | ||||

| 3 | 60 | 50 | G225.6051 | C405/6A/50 | G4556050 | G50560/50 | 6555/6050 | G6056051 | ||

Features

ASTM A36 steel grating is manufactured using low carbon steel with excellent weldability and formability. It is known for its high strength and exceptional load-bearing capacity. This makes A36 steel grating ideal for heavy-duty applications in industrial settings, such as construction sites, manufacturing plants, and petrochemical facilities. It offers enhanced resistance against impact, heat, and corrosion, ensuring a longer lifespan even in harsh environments.

Galvanized steel grating is manufactured by coating steel with a layer of zinc, offering superior protection against corrosion and rust. The galvanization process enhances the longevity of the grating, making it suitable for outdoor installations or areas exposed to moisture and corrosive elements. Galvanized grating is commonly used in pedestrian walkways, drainage systems, and platforms, where its anti-slip surface adds an extra layer of safety.

The main difference between ASTM A36 steel grating and galvanized steel grating lies in their corrosion resistance properties. While ASTM A36 grating provides a base level of corrosion resistance, the galvanized coating on steel grating offers superior protection, significantly extending its lifespan. Galvanized steel grating is recommended for applications where corrosion prevention is of utmost importance.

Application

Steel grating, a versatile and durable product, has gained significant popularity due to its multiple applications across various industries. Composed of interconnected steel bars or plates, steel grating offers exceptional strength, stability, and drainage capabilities.

1. Industrial Sector:

The industrial sector extensively employs steel grating for its unmatched strength and safety features. It is commonly used as flooring within factories and warehouses, providing a stable surface for heavy machinery and giving workers a secure footing. Steel grating is also utilized for catwalks, raised platforms, and mezzanines, offering a safe passage for workers to access different areas within the facility.

2. Construction Industry:

In the construction industry, steel grating is indispensable. It is extensively used as scaffolding platforms, providing a sturdy and safe working surface for workers at elevated heights. With its high load-bearing capacity, steel grating ensures the safety of construction personnel during various stages of a project. Moreover, steel grating can be customized to meet specific requirements, making it a preferred choice for constructing walkways, staircases, and drainage covers within buildings.

3. Transportation Sector:

Due to its excellent strength-to-weight ratio, steel grating finds numerous applications in the transportation sector. It is widely used for creating robust, non-slip walkways and stair treads in vehicle maintenance facilities, airports, train stations, and shipyards. These grating solutions enhance safety and enable efficient movement, even in harsh weather conditions.

4. Energy and Oil Industry:

The energy and oil industry relies heavily on steel grating for its durability and resistance to corrosion. Steel grating is commonly used in oil refineries, power plants, and chemical processing facilities. It serves as an ideal flooring solution, especially in areas exposed to liquids, chemicals, and extreme temperatures, ensuring worker safety and preventing accidents.

5. Commercial and Architectural Applications:

Steel grating is also finding its way into commercial and architectural projects. Its aesthetic appeal, coupled with its functional advantages, makes it an excellent choice for creating stylish facades, sunshades, and decorative screens. Steel grating can also be used as artistic elements in urban landscapes, offering both visual appeal and practicality.

Packaging & Shipping

PRODUCT INSPECTION

FAQ

1. Are you a manufacturer or just a trading company?

We are manufacturer, and established in 2012 and have 10 years of industry experience in this field.

2. Can I get a piece of your products sample?

Yes, free samples will be provided anytime.

3. How do you make our business long-term and in good relationship?

. We make products with good quality and competitive price to ensure our customers benefit;

4. How to get a quotation ?

Provide us with the production requirements, size, quantity and arrival port, and we will promptly quote .

5.When will the goods be delivered ?

It depends on the specific order quantity, generally 15~20 days .

6.What makes your products different from other company’s?

Provide free design service, customization and warranty service, with strictly quality control and very competitive price.