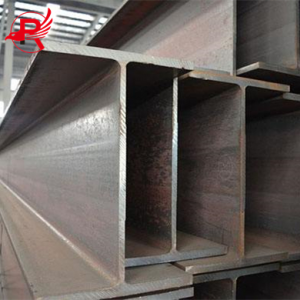

ASTM H-Shaped Steel h Beam Carbon h Channel Steel

Product Detail

The specific details of H-shaped steel typically include dimensions such as the height, flange width, web thickness, and flange thickness. These details vary based on the specific design and intended application of the H-beam. H-beams are available in a range of sizes and specifications, allowing for flexibility in meeting diverse construction needs.

In addition to their use in buildings and bridges, H-beams are also employed in various industrial applications, such as supporting heavy equipment and machinery. The versatility and strength of H-shaped steel make it essential for creating stable and robust structures and frameworks in both architectural and industrial settings

|

SPECIFICATIONS FOR H-BEAM |

|

| 1. Size | 1) Thickness:5-34mm or customized |

| 2)Length:6-12m | |

| 3)Web Thickness:6mm-16mm | |

| 2. Standard: | JIS ASTM DIN EN GB |

| 3.Material | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)industrial high-rise building |

| 2)Buildings in Earthquake Prone Areas | |

| 3)large bridges with long spans | |

| 6. Coating: | 1) Bared

2) Black Painted (varnish coating) 3) galvanized |

| 7. Technique: | hot rolled |

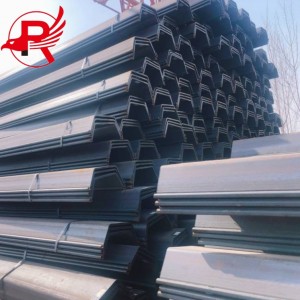

| 8. Type: | H type sheet pile |

| 9. Section Shape: | H |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent

2) Free for oiled&marking 3) All goods can be checked by third party inspection before shipment |

| Divis ibn (depth x idth |

Unit Weight kg/m) |

Sandard Sectional Dimension (mm) |

Secional Area cm² |

||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

Features

H-shaped steel in the packaging and transportation process need to pay attention to the following matters:

Packaging: H-shaped steel needs to be properly packaged before transportation to prevent surface damage. Common packaging materials include wooden pallets, wooden boxes, plastic packaging and so on. The packaging material needs to be strong and stable enough to ensure that the H-shaped steel will not be squeezed or bumped in transit.

Marking: The weight, size, model and other information of H-shaped steel should be clearly marked on the package to facilitate identification during transportation and use.

Lifting and handling: When lifting and handling H-beams, appropriate lifting equipment and hooks are needed to ensure safe and stable operation.

Transportation: Select the appropriate means and methods of transportation to ensure that the H-shaped steel will not be subjected to serious vibration and vibration during transportation.

Application

Applications of H Section Beams:

The versatility of H section beams makes them indispensable in a multitude of construction projects. H section beams serve as primary structural elements in the construction of bridges, providing the backbone for strong and durable spans. Their ability to withstand heavy loads and resist lateral forces makes them ideal for high-rise buildings, ensuring stability and accommodating large floor openings. Additionally, H section beams find applications in industrial settings, supporting heavy machinery and providing ample raised storage space.

H section beams are also widely used in the shipbuilding industry, where their superior load-bearing capacity and resistance to corrosion make them ideal for constructing various marine structures. Moreover, modern architectural designs often employ H section beams as aesthetically pleasing design elements, adding an industrial touch to contemporary structures.

Packaging & Shipping

Packaging:

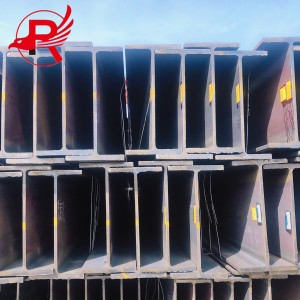

Stack the sheet piles securely: Arrange the H-Beam in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack of sheet piles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of sheet piles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.