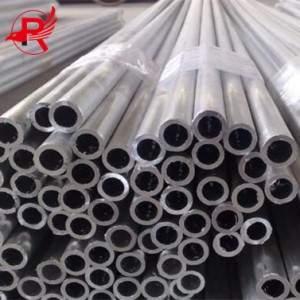

Aluminum Tube Supplier 6061 5083 3003 Anodized Round Pipe

Product Detail

Here are some key details about aluminum pipes:

Material: Aluminum pipes are made from aluminum, usually with alloying elements to enhance specific properties such as strength or corrosion resistance. Common alloy series used for aluminum pipes include 6xxx, 5xxx, and 3xxx series.

Dimensions: Aluminum pipes are available in various sizes and dimensions, including outer diameter (OD), inner diameter (ID), and wall thickness. These dimensions are typically specified in millimeters or inches.

Tolerance: The dimensions of aluminum pipes should adhere to specific tolerance requirements to ensure accuracy and consistency in size.

Surface Finish: Aluminum pipes generally have a smooth surface finish. They can be left untreated or undergo treatments such as polishing or anodizing to improve aesthetics or increase corrosion resistance.

Mechanical Properties: The mechanical properties of aluminum pipes vary depending on the alloy and temper. Some commonly cited properties include tensile strength, yield strength, elongation, and hardness. Specific properties can be chosen to suit the intended application.

Chemical Composition: Aluminum pipes have a specific chemical composition governed by industry standards or customer requirements. The composition can include aluminum as the primary element along with alloying elements like copper, magnesium, manganese, or zinc.

Corrosion Resistance: Aluminum pipes are known for their excellent corrosion resistance. The natural oxide layer that forms on the surface of aluminum provides a protective barrier against oxidation and corrosion. Additionally, certain alloying elements can enhance the corrosion resistance of aluminum pipes in different environments.

Joining Methods: Aluminum pipes can be joined using various methods such as welding, brazing, or mechanical fittings. The selection of joining method depends on factors like the pipe size, application requirements, and the specific alloy used.

It is important to consult specific industry standards or supplier specifications for detailed technical information about a particular aluminum pipe, as the details may vary depending on the intended use and alloy selected.

SPECIFICATIONS FOR ALUMINUM PIPES

|

Aluminum Tube/Pipe

|

||

|

Standard

|

ASTM, ASME, EN, JIS, DIN, GB

|

|

|

Specifcation for round pipe |

OD

|

3-300 mm,or customized

|

|

WT

|

0.3-60 mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

|

Specification for square pipe

|

SIZE

|

7X7mm- 150X150 mm,or customized

|

|

WT

|

1-40mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

| Material Grade |

1000 series: 1050, 1060, 1070, 1080, 1100, 1435, etc

2000 series: 2011, 2014, 2017, 2024, etc 3000 series: 3002, 3003, 3104, 3204, 3030, etc 5000 series: 5005, 5025, 5040, 5056, 5083, etc 6000 series: 6101, 6003, 6061, 6063, 6020, 6201, 6262, 6082, etc 7000 series: 7003, 7005, 7050, 7075, etc |

|

|

Surface treatment

|

Mill finished, anodized, powder coating, Sand blast, etc

|

|

|

Surface colors

|

Nature, silver, bronze, champagne, black, gloden or as customized

|

|

|

Usage

|

Auto /doors/decoration/construction/curtain wall

|

|

|

Packing

|

Protective film+plastic film or EPE+kraft paper,or customized

|

|

SPECIFIC APPLICATION

Aluminum pipes find application in various industries due to their beneficial properties. Here are some common applications of aluminum pipes:

HVAC Systems: Aluminum pipes are widely used in heating, ventilation, and air conditioning (HVAC) systems for their excellent thermal conductivity. They are used as conduits for coolant or refrigerant flow.

Plumbing Systems: Aluminum pipes are used for plumbing systems, particularly in residential and commercial buildings. They are lightweight, easy to install, and resistant to corrosion, making them a suitable choice for carrying water, gases, or sewage.

Automotive Industry: Aluminum pipes are employed in several automotive applications, including radiator systems, air intake systems, turbocharger piping, and exhaust systems. They help in minimizing weight while providing efficient heat transfer and improved fuel efficiency.

Industrial Processes: Aluminum pipes are utilized in industrial processes that involve the transport of liquids or gases. They are commonly used in industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and wastewater treatment.

Solar Energy Systems: Aluminum pipes are used in solar thermal energy systems for their ability to efficiently transfer heat. They are often used as piping in solar water heating systems.

Construction and Architecture: Aluminum pipes are employed in construction and architecture for various purposes, including structural applications, handrails, curtain walls, and façade systems. They offer durability, lightweight construction, and design flexibility.

Electrical Conductivity: Aluminum pipes, especially those made from high-conductivity alloys, are utilized in electrical applications. They are used for electrical wirings, power transmission and distribution, and busbars due to their excellent electrical conductivity.

Furniture and Interior Design: Aluminum pipes are popular in the furniture and interior design industries. They are used in items such as chairs, tables, shelving, and curtain rods, as they provide a sleek, modern look and are easily customizable.

Packaging & Shipping

When it comes to packaging and shipping aluminum pipes, it is essential to ensure proper protection to prevent any damage during transit. Here are some guidelines to consider:

Packaging Materials: Use sturdy and durable packaging materials such as cardboard tubes or boxes. Ensure that they are of the appropriate size to fit the aluminum pipes securely.

Padding and Cushioning: Place sufficient padding and cushioning material, such as bubble wrap or foam, around the aluminum pipes within the packaging. This will help absorb any shocks or impacts during transportation.

Secure the Ends: To prevent the pipes from sliding or shifting within the packaging, secure the ends by either taping or capping them tightly. This will add stability and minimize the risk of damage.

Labeling: Clearly label the packaging with information such as "Fragile," "Handle with Care," or "Aluminum Pipes." This will alert handlers to take necessary precautions during shipping.

Secure Packaging: Seal the packaging securely with strong packaging tape to ensure that it stays intact throughout its journey.

Consider Stacking and Overlapping: If multiple aluminum pipes are being shipped together, consider stacking them in a way that minimizes movement and overlapping. This will help distribute weight evenly and reduce the risk of damage.

Choose Reliable Shipping Services: Opt for a reliable shipping service provider that specializes in handling fragile or sensitive goods.