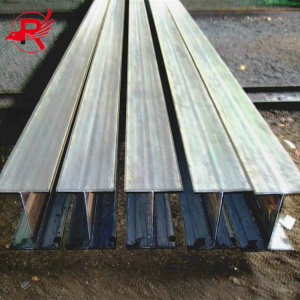

China Factory of Silicon Steel Sheet Cold Rolled Silicon Steel Coil

Product Detail

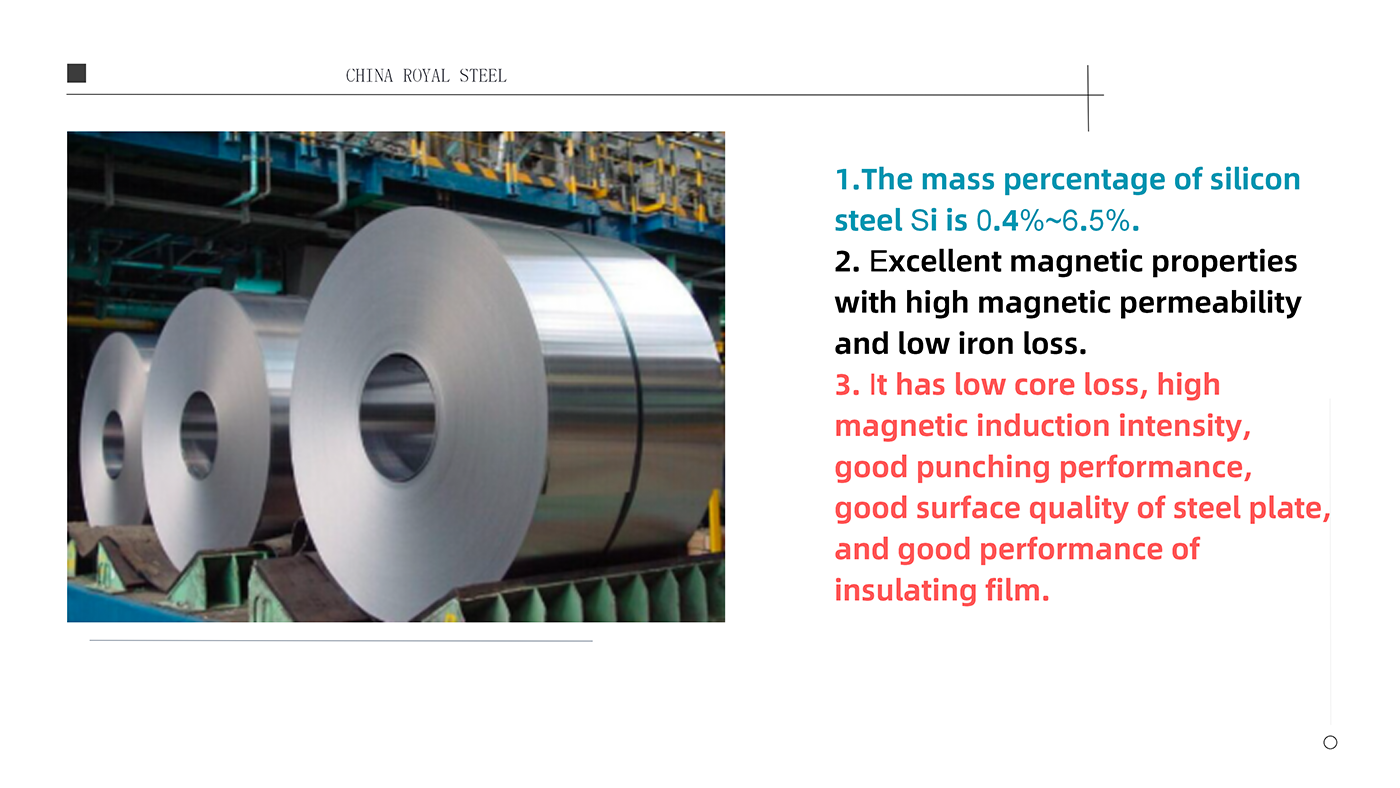

Silicon steel sheets for electrical purposes have excellent electromagnetic properties and are indispensable and important magnetic materials in the power, telecommunications and instrument industries.

Features

(1) Classification of silicon steel sheets

A. Silicon steel sheets can be divided into low silicon and high silicon according to their silicon content. Low silicon wafers contain less than 2.8% silicon. They have a certain mechanical strength and are mainly used to make motors, commonly known as motor silicon steel sheets. High silicon wafers contain 2.8%-4.8% silicon. They have good magnetism but are brittle and are mainly used for Used in manufacturing transformer cores, commonly known as transformer silicon steel sheets. There is no strict boundary between the two in actual use, and high-silicon wafers are commonly used to manufacture large motors. B. According to the production and processing technology, it can be divided into two types: hot rolling and cold rolling. Cold rolling can be divided into two types: grain non-oriented and grain oriented. Cold-rolled sheets have uniform thickness, good surface quality, and high magnetic properties. Therefore, with the development of industry, hot-rolled sheets have a tendency to be replaced by cold-rolled sheets (our country has clearly required the discontinuation of the use of hot-rolled silicon steel sheets, which is what was previously called "Replacing heat with cold").

| Trademark | Nominal thickness(mm) | 密度(kg/dm³) | Density(kg/dm³)) | Minimum magnetic induction B50(T) | Minimum stacking coefficient (%) |

| B35AH230 | 0.35 | 7.65 | 2.30 | 1.66 | 95.0 |

| B35AH250 | 7.65 | 2.50 | 1.67 | 95.0 | |

| B35AH300 | 7.70 | 3.00 | 1.69 | 95.0 | |

| B50AH300 | 0.50 | 7.65 | 3.00 | 1.67 | 96.0 |

| B50AH350 | 7.70 | 3.50 | 1.70 | 96.0 | |

| B50AH470 | 7.75 | 4.70 | 1.72 | 96.0 | |

| B50AH600 | 7.75 | 6.00 | 1.72 | 96.0 | |

| B50AH800 | 7.80 | 8.00 | 1.74 | 96.0 | |

| B50AH1000 | 7.85 | 10.00 | 1.75 | 96.0 | |

| B35AR300 | 0.35 | 7.80 | 2.30 | 1.66 | 95.0 |

| B50AR300 | 0.50 | 7.75 | 2.50 | 1.67 | 95.0 |

| B50AR350 | 7.80 | 3.00 | 1.69 | 95.0 |

Application

(2) Silicon steel sheet performance indicators

A. Low iron loss. The most important indicator of quality is the iron loss value. The lower the iron loss, the higher the grade and the higher the quality.

B. High magnetic induction intensity. Silicon steel sheets can obtain higher magnetic induction under the same magnetic field. The size and weight of the motor or transformer core made with it are relatively small, which can save silicon steel sheets, copper wires and insulating materials. C. The stacking coefficient is high. The surface of the silicon steel sheet is smooth, flat and uniform in thickness, and the stacking coefficient of the core is improved.

D. Good film processing properties. This is even more important for manufacturing small and micro motor cores.

E. The surface has good adhesion and weldability to the insulating film.

F. Magnetic aging

G. Silicon steel sheets must be delivered after annealing and pickling.

Packaging & Shipping

silicon steel products needs to pay attention to moisture-proof and shock-proof during transportation. First of all, the packaging material should have a certain moisture-proof performance, such as the use of moisture-proof cardboard or the addition of moisture absorption agents; Secondly, in the process of packaging, the product should try to avoid direct contact with the ground and other hard objects, in order to prevent damage caused by vibration or extrusion during transportation.

FAQ

Q1. Where is your factory ?

A1: Our company’s processing center is located in Tianjin, China.Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, steel sheet pile, steel strut,etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and

best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait,

Egypt, Turkey, Jordan, India, etc.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free. Customized samples will take about 5-7days.